Capabilities

Experience

Our Team

The Sabre team is made up of experienced professionals, including a high ratio of Journeyperson machinists who are highly trained in manual and CNC machining. Their knowledge and experience gives us the capability to deliver on custom-machining or large-quantity production orders with the standard our clients have come to expect.

Our 4” Deep Hole Drill here can produce large scale aluminum steam valves for a hydro project.

Our 4” Deep Hole Drill here can produce large scale aluminum steam valves for a hydro project.

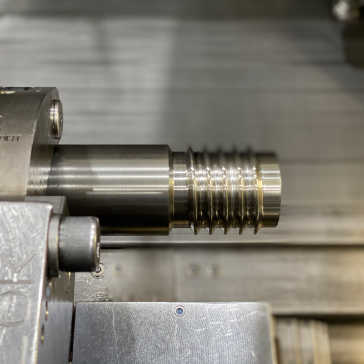

We operate high-quality, well-maintained CNC machines that can perform a variety of tasks and ensure excellent lead times.

Our equipment includes:

- Lathes and mills (both large and small)

- Robotic cells (allowing lights-out machining)

- Deep-hole gun drilling

- Swiss machines (small envelope, highly robotic, multiple tools, small parts)

- Deep-hole boring

- Ejector drilling (including large sizes)

- Ejector drilling (including large sizes)

ALL SYSTEMS GO

The first machine to arrive in our Saskatoon shop, the Mazak

QTN450-II m got us started on March 11, 2011. And we continue to add capabilities and equipment.

We expect to see the Full Five Axis Multi-task here in November.

Certifications

It’s not enough for us to claim we know what we’re doing — we need to back it up.

Industry certification and third-party audits regularly test us to make sure we’re up-to-date with the latest industry best practices.

-

Full seats of Mastercam 2021 / Verisurf

-

-

Full Quality Assurance using a CMM and high-quality measuring tools

-

-

Fully ISO 9001: 2015 Certified and AS9100D

Aerospace and Defense Contracting -

-

Registered under TRC and BSI

-

-

Download ISO Certificates